We are offering industrial valves like gate valves, globe valves, check valves, ball valves, needle valves, flanged end valves, forged steel valves, cast steel valves, teflon valves, stainless steel valves and brass valves.

We are offering industrial valves like gate valves, globe valves, check valves, ball valves, needle valves, flanged end valves, forged steel valves, cast steel valves, teflon valves, stainless steel valves and brass valves.

Our clients can avail from us a wide gamut of Valves which manufactured using forged steel & cast steel. We offer different kind of valves to our clients mainly in Gate, Globe and Chek type. The range has received ratings such as 800/1500/2500 in SW/SCRD ends, 150/300 in Flanged ends. Valves are highly appreciated by our clients as these are manufactured using superior quality raw material such as A 105/A 182 F-304, 316/F-11 ,F-22 A 216 Gr WCB/ A 351 GR CF8/CF8M.

Our clients can avail from us a wide gamut of Valves which manufactured using forged steel & cast steel. We offer different kind of valves to our clients mainly in Gate, Globe and Chek type. The range has received ratings such as 800/1500/2500 in SW/SCRD ends, 150/300 in Flanged ends. Valves are highly appreciated by our clients as these are manufactured using superior quality raw material such as A 105/A 182 F-304, 316/F-11 ,F-22 A 216 Gr WCB/ A 351 GR CF8/CF8M.

We have in store for our clients a wide range of Ball Valves which is offered in 2/3 piece design and connections which robust and easy to maintain. These are availed in teflon, delrin, peak seats and are also customized as per client's requirement. Our organization uses quality raw material for fabricating this range to ensure durability, corrosion resistance and reliability. The range is available in following specifications:

We have in store for our clients a wide range of Ball Valves which is offered in 2/3 piece design and connections which robust and easy to maintain. These are availed in teflon, delrin, peak seats and are also customized as per client's requirement. Our organization uses quality raw material for fabricating this range to ensure durability, corrosion resistance and reliability. The range is available in following specifications:

| Range | 1/8” to 1” threaded and 1/8 OD to 1”OD 4mm OD to 25mm OD |

| End connection | BSP/NPT/BSPT |

| MOC | SS 304, SS 316, Brass monel, Hast alloy, Teflon, CS |

| Available | 2-way on-off, 3, 4 or 5 way switching models |

• Heavy directional black fenolic handle or lever handle

• Blow-out proof bottom loaded stem

• Low operating torque and with panel mounting facilities

• Series of end connections 1/4" to 1" NPT, BSP

•Male or female threaded ends and 1/4", 3/8" and 1/2" single or twin ferrule tube fitting ends

• Floating Ball design for positive sealing

• It has maximum working pressure of 3000 PSI at 20 o C to 250 o C with PTFE seat

•High Pressure Ball Valve with 6000 PSI with polyaman or KEF-F seats

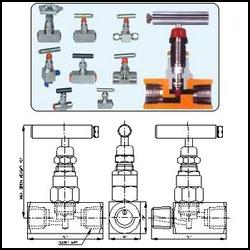

Our clients can avail from us an extensive range of Needle Valves which is fabricated using bar stock forged material. These are precisely designed and manufactured under the expert supervision of our professionals. The valves are suitable for isolating, calibrating and draining the process lines. We offer the range in following specifications:

• Range : 1/8” to 1” threaded and 1/8 OD to 1”OD 4 mm OD to 25mm OD

Our clients can avail from us an extensive range of Needle Valves which is fabricated using bar stock forged material. These are precisely designed and manufactured under the expert supervision of our professionals. The valves are suitable for isolating, calibrating and draining the process lines. We offer the range in following specifications:

• Range : 1/8” to 1” threaded and 1/8 OD to 1”OD 4 mm OD to 25mm OD

• End connection: BSP/NPT/BSPT

• MOC: SS 304, SS 316, Brass monel, Hast alloy, Teflon, CS

• Bar stock Body construction

• Straight or Angle Pattern with Panel Mounting optional

•Metal to Metal or Stellited seats

• Non-rotating ball tip optional(Vee Regulating one piece or non-regulating) and stem threads Rolled and hard plated and tie stellied

•Packed with 2 piece P.T.F.E. which offers zero leak

• Assortment of end connections include single or twin ferrule tube fittings having male or female N. P. T. and I. S. O., DIN and JIS tapered pipe ends

• Maximum working pressure ranges from 6000 PSI (400 bar) at 200 o C. 10000 PSI (700 bar) at 120 o C.